APO SITE AIR COMPRESSOR SYSTEMS

There

are 2 separate compressed air systems on site that function independently.

These systems can backup each other in case of an emergency. Depending on the

situation the backup system can support operations for either a short time or

for days.

System No. 1: This system provides compressed air to:

3.5m

primary mirror support

2.5m --all

1m -- all

.6m -- all

Ops

bldg outlets

System No. 2: This system provides compressed air to:

Shop

Garage

3.5m

Eyelids/Mirror Cell

3.5m

Enclosure lock

3.5m

Instrument purges

.5m

Back-up PMSS pumps

System No.1

Compressed air is

provided by two Kaeser screw compressors in the

boiler room. Each compressor can

handle the load by itself and runs for 12 hrs each day, then switches over to

the other compressor. Air from the

compressors goes into an air tank in the boiler room. The air is filtered and

dried in the boiler room before being distributed. There are additional air

tanks at the 3.5m ground level, 2.5m, 1m, and .6m telescopes. Pressure runs at

either 109 or 115 psi depending on which compressor is operating. Each compressor and dryer system

provides automatic redundancy. If

the load becomes too much for one compressor to handle (pressure drops due to

leak for instance) then the second compressor will come on load automatically.

There are 3 operating

modes for these compressors:

On

load –generating compressed air;

Off

Load – motor running but not building pressure;

Standby-

motor off unless pressure drops.

The largest consumer of

this air is the 2.5m PMSS system.

The air tanks are sized

to provide 15 minutes of compressed air to support the mirrors in the event of

a compressor fault.

There are two

alarms: A low pressure alarm in

the Ops Building extension on the north facing wall which alerts if the

pressure drops below 85 psi; and an alarm in the shipping/receiving area of the

Ops Bldg Service Area which alerts if there is too much moisture in the air.

(This is critical for the instrument purge systems in the 2.5m but not for

anything else) Both alarms need to

be addressed quickly.

In the event of loss

of pressure, both the 2.5m and 3.5m should be moved to zenith and held in that

position. Once the pressure drops

below 70 psi, do not slew either telescope in altitude.

The Kaeser

compressors operate via a computer SIGMA controller. Compressors labeled #1 and #2 are identical; compressor #3

is slightly different. If the

compressor senses a maintenance issue or is due for maintenance based on

runtime, an orange LED will blink by the wrench symbol. No immediate action is required.

If the compressor

faults, a red LED will blink. To clear this, you press the button with the two

half moon symbols. Then press the green ÒIÓ button to restart the compressor. If necessary, try recycling the power

using the circuit breaker behind each unit, then press the green ÒIÓ

button. If this fails, call for

assistance. (see Fig 1)

If the motor current

trips, common with power outages, you can reset this by opening the electrical

compartment on the right hand side of the compressor. There is high voltage in this compartment unless power has

been turned off. Turn the power

off (turn off circuit breaker behind unit), then open compartment using the

cross shaped key (see Fig 4). This

key is kept near each compressor.

Depress the blue reset button on the contactor. After depressing the blue button (see

Fig 5), close the compartment, turn circuit breaker on then, after the unit

initializes, press the green ÒIÓ button.

System No. 2

Compressed air is

provided by one Kaeser screw compressor in the

garage. There is also a Speedaire piston compressor that can be used as an

emergency backup. The Speedaire is not an automatic backup and requires a knife

switch be thrown to bring it on line.

(see Fig 3)

A twin tower dryer and

filters clean and dry the air before it leaves the garage. The Speedaire

tank is the only air storage tank for System No. 2.

There are currently no

alarms on System No. 2.

Systems No. 1 and No. 2

can be interconnected to provide an additional level of backup. Note that System No. 1 can back up

System No. 2 completely. However,

System No. 2 can only backup System No. 1 when operating on the Kaeser compressor.

********* Do not operate

System No. 1 on the Speedaire compressor. Doing so will burn up the Speedaire compressor within an hour ************

To operate System No. 1

from System No. 2:

Close

valve labeled Ò Compressor 2 outlet NOÓ in boiler room

Close

valve labeled Ò #1 outlet NOÓ in boiler room

Open the valve labeled ÒBU Supply NCÓ in the

boiler room (see Fig 2)

To operate System No. 2

from System No. 1:

Open the valve labeled ÒBU Supply NCÓ in the

boiler room (see Fig 2)

Anytime you operate both

systems from one source you need to conserve as much air usage as

possible. Avoid operating multiple

air devices simultaneously.

Figure 1

Kaeser screw compressor controller

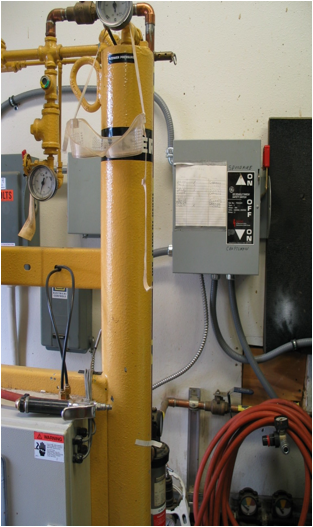

Figure

2

Back up supply valve

Figure

3

System

No. 2 backup knife switch (with

old craftsman legend)

Figure

4

Electrical compartment above air filters (R/H side)

Shown with

key in latch

Figure

5

Motor current trip (blue reset button)

Inside compartment above air filter